An ultrasonic flow meter (UFM) is a flow measurement device that uses sound waves to measure the velocity of a fluid. It is known for providing a non-invasive and non-contact method of flow measurement. Instead of inserting a probe into pipes, the device attaches to the outside of a pipe and emits sound waves through the pipe wall to measure the flow. This method provides an extremely accurate reading without disrupting the flow of the fluid.

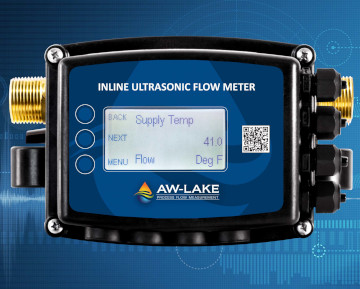

One of the most significant advantages of an ultrasonic flow meter is its accuracy. The AW-Lake WIN Ultrasonic Flow Meter, for example, has an accuracy of +1.0% of reading over 25:1 turndown. This means that the device can accurately measure flow rates from very low to very high rates without sacrificing accuracy.

Another advantage of an ultrasonic flow meter is that it has no moving parts. This reduces the need for maintenance and repair over time, significantly increasing the cost-effectiveness of these devices. Furthermore, because they are non-invasive, they are simple and easy to install.

However, there is one notable disadvantage to UFMs - they do not always provide a pulse output. This may be problematic for some applications that require pulse output signals. In these cases, a pulse output flow meter may be more suitable.

A pulse output flow meter is a type of flow meter that measures flow rate by counting the number of pulses produced by a sensor per unit of time. These sensors are commonly used in turbine, positive displacement, and electromagnetic flow meters. Pulse output flow meters are beneficial for applications that require precise measurements and controlling the flow rate.

In conclusion, flow measurement devices like the AW-Lake WIN Ultrasonic Flow Meter are essential for many industrial applications. Although it lacks pulse output, ultrasonic flow meters are non-invasive, non-contact, and highly accurate. They also have no moving parts, reducing maintenance costs and increasing overall device lifespan. For applications in which pulse output is essential, pulse output flow meters may be the preferred option. Regardless of which option businesses choose, both technologies are critical components in maintaining the efficiency and reliability of industrial systems.